What do you get when you combine Lean Manufacturing and Marie Kondo?

Answer: 5S

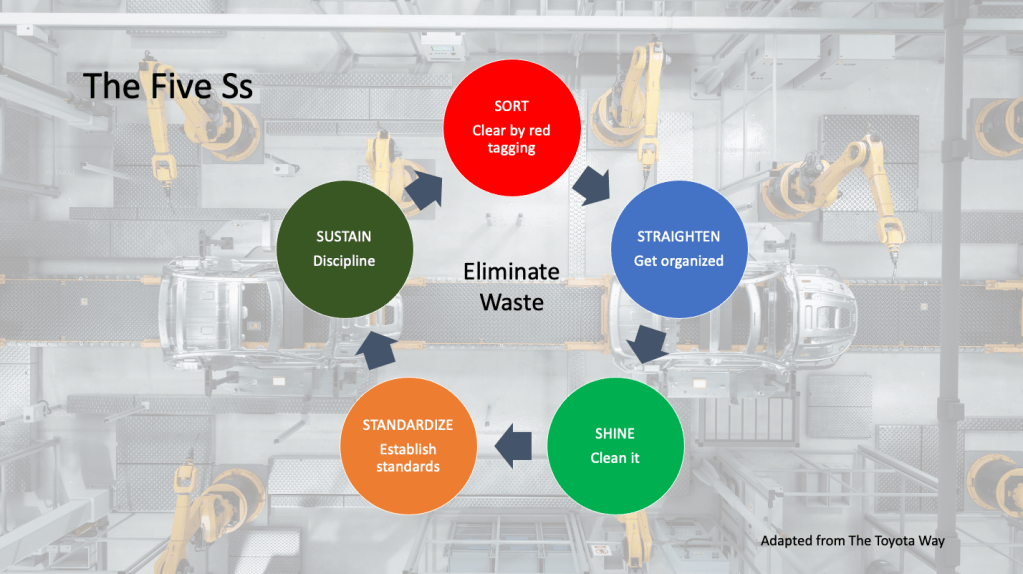

What is 5S?

5S is a lean methodology that results in an organized, uncluttered, clean workplace both physically and mentally. A workplace that nurtures and sustains quality, productivity and improvement.

Each of the five S’s represents a Japanese word phonetically starting with ‘S’ alongside an English translation.

1. Seiri: Sort

2. Seiton: Straighten

3. Seiso: Shine

4. Seiketsu: Standardize

5. Shitsuke: Sustain

5S was developed in Japan and popularized by Toyota as part of their Toyota Production System for lean manufacturing. It was created to nurture and sustain a clean and tidy manufacturing workplace environment and culture.

Benefits resulting from implementing a lean 5S manufacturing program include:

- Improved safety

- Higher equipment availability

- Lower defect rates

- Reduced costs

- Increased production agility and flexibility

- Improved employee morale

- Better asset utilization

- Enhanced enterprise image to customers, suppliers, employees, and management

As I looked at the pattern of steps formed by the 5 S’s and its benefits, it struck me how well it fit two of my current coaching pursuits:

- Looking for alternative ways to change and improve my client’s organization.

- Leaning more into Lean tools.

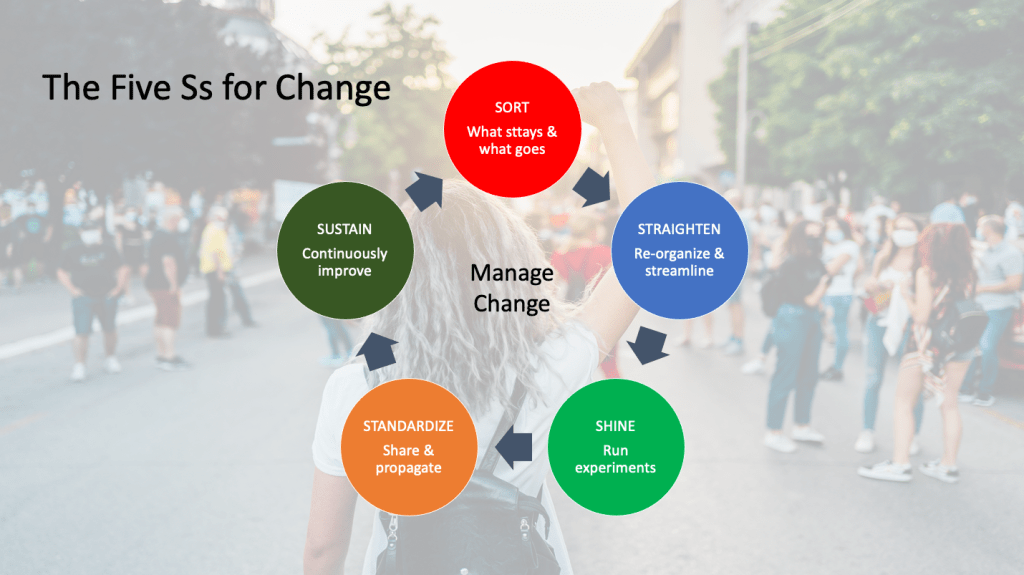

What if I were to apply and test the 5S approach to managing and navigating change?

Here’s how I adapted the 5S methodology for use as a change tool. In general, 5S can be used as a way to leverage a change to see, question and challenge the current status-quo. More specifically,

- Seiri: Sort – Decide what to keep and what to get rid of.

- Seiton: Straighten – Re-organize around what is kept and decide on stream-lining who does what.

- Seiso: Shine – Run experiments to test and refine change implications.

- Seiketsu: Standardize – Capture, communicate and propagate tested and verified change implications.

- Shitsuke: Sustain – Instill a culture of collective accountability and continuous improvement.

My expected benefits from using it as a change tool include:

- Tapping into latent capabilities within people

- Increased ownership, collaboration and self organization

- Increased agility and flexibility

- Improved employee morale and engagement

- Improved processes

- Lower defect rates

- Reduced costs

- Higher stakeholder and customer satisfaction

I decided to test this with a couple of change candidates:

- A technology platform team that reverted from an agile delivery structure to a traditional delivery structure.

- A pair of Scrum teams that lost its Scrum Master

Test 1: Technology Platform Team Re-structures

What was the change?

A tribe composed of multiple squads and initiative teams decides to abandon an existing agile organizational structure and revert back to a traditional delivery team structure while maintaining a desire to leverage agile ways of working.

Managing the change through a 5S lens…

| 5S Step | What it means for the change? | Questions to ask |

| Sort | Decide what to keep and what to get rid of | Why are we reverting back to the old structure? What happens to the existing squads and teams? What about Scrum? How will we manage the backlog? |

| Straighten | Re-organize around what is kept and decide on stream-lining who does what | What will change with the PO and SM roles? What roles will be added or removed? How will we prioritize the backlog? |

| Shine | Run experiments to test and refine change implications | What will a combined visual Scrum board for all teams achieve? What can be improved with the prioritization process? What can we do to develop the PO, SM and other roles? |

| Standardize | Capture, communicate and propagate tested and verified change implications | How might we codify or formalize our ways of working? What will we need from others and how will they know? |

| Sustain | Instill a culture of collective accountability and continuous improvement | Who will be accountable for delivery results? How will we review our performance and continue to improve? |

Test 2: No Scrum Master

What was the change?

Two Scrum teams operating with a dedicated but shared Scrum Master find themselves with no Scrum Master when the Scrum Master resigns.

Managing the change through a 5S lens…

| 5S Step | What it means for the change? | Questions to ask |

| Sort | Decide what to keep and what to get rid of | Why did the SM leave? How has this impacted the PO and team members?How will the team operate without a Scrum Master? Will the Scrum Master be backfilled? If not, why not? |

| Straighten | Re-organize around what is kept and decide on stream-lining who does what | What will be the process for rotating temporary volunteer Scrum Masters? What Scrum events will in scope for the volunteer Scrum Masters? |

| Shine | Run experiments to test and refine change implications | How might a team member and the team benefit from volunteer Scrum Masters? What support will volunteer Scrum Masters need? How might this experience affect recruitment of a future Scrum Master? |

| Standardize | Capture, communicate and propagate tested and verified change implications | How might we codify or formalize our ways of working? What will we need from others and how will they know? |

| Sustain | Instill a culture of collective accountability and continuous improvement | What will this do to the future relationship between Scrum Master and the team? Between Scrum Master and PO? Between Scrum Master and the organization? |

The real power for me in using 5S as a change tool is its ability to prompt the right questions to ask. Questions that will explore and expand the benefits and pitfalls of the change so that it will last.

At least until the next change.

Coming back to Marie Kondo, I believe 5S invites and encourages us to…

“Discard everything that does not spark joy”

– Marie Kondo